Some examples include pin constraints, bearing loads, or bolt connections. Second are simulation features or modeling objects specific to CAE that are intuitive for engineers to use. “First is that there is no data translation required and no worries about import failures or errors when used with Creo Direct or Parametric. This enables quick and easy what-if studies, automated sensitivity, and optimization studies.īuchowski says that there are other things to be excited about. Geometric based modeling in Creo Simulate preserves the simulation model as the CAD geometry is modified in Creo Parametric or Creo Direct. In this manner, you can enjoy all the benefits of a best in class role-specific application as well as the data continuity of a more traditional architecture. This phenomenon can reduce the risk of error, help you meet design requirements, and potentially open the door for investigating more design alternatives.īy leveraging the common data model, designs analyzed in the separate Creo Simulate application are accessing all the same geometry and meta-data, such as material properties, as are accessed by the authoring applications (Creo Parametric and Creo Direct). PTC says that when you make the design-simulation loop smaller it increases the number of cycles that can be performed. In addition, because no translation or import is required when simulating Creo Direct or Parametric models, there is no penalty in rework for starting to run your simulations sooner or more often in a design cycle. Recent enhancements include an expansion of PTC’s nonlinear structural and thermal capabilities with support for more sophisticated analyses such as plasticity, large displacement, and sliding contact with load stepping – all fully coupled in a single analysis.

#CREO SIMULATE SOFTWARE#

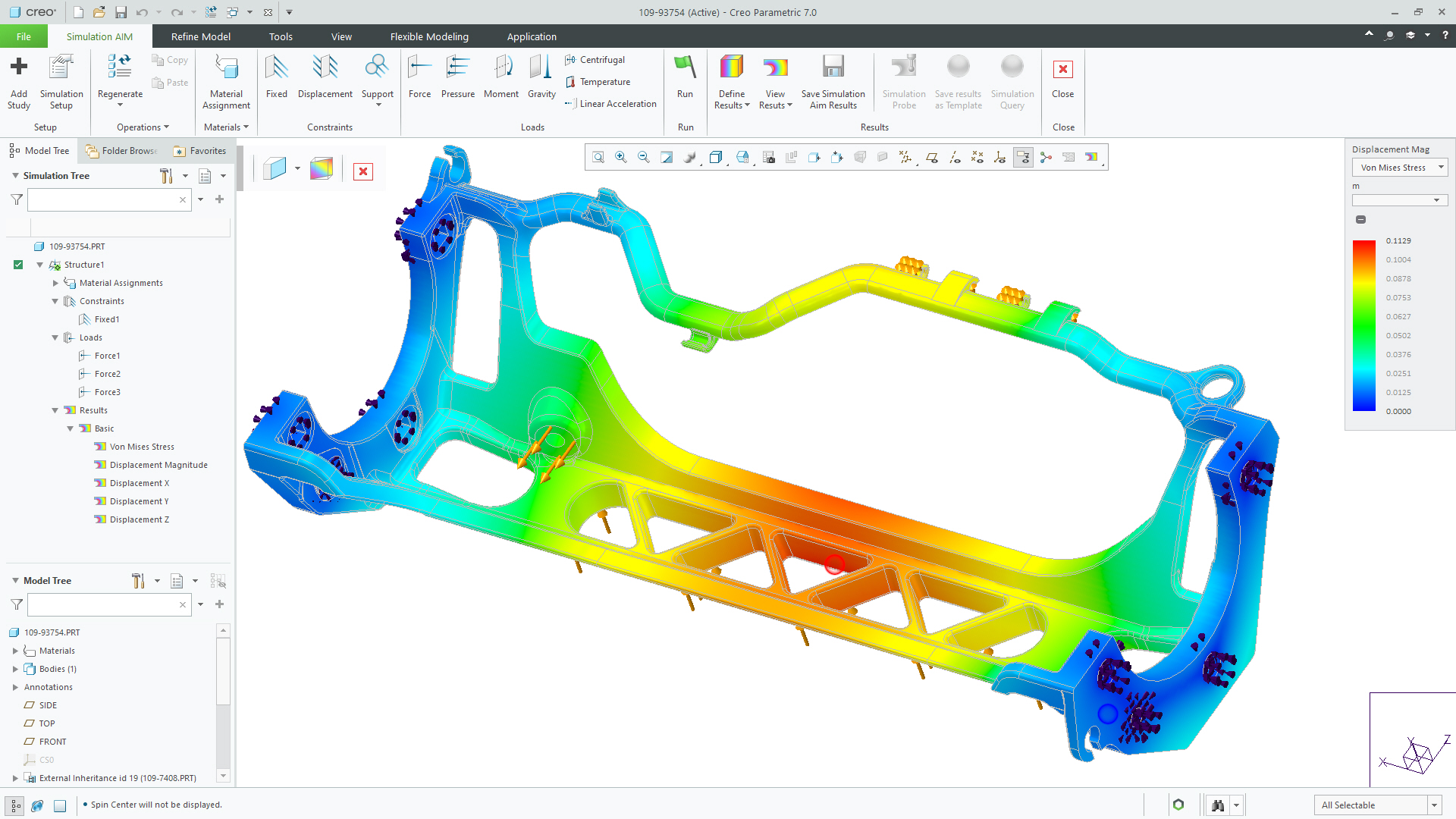

The software supports a variety of analysis types ranging from structural static and steady state thermal to dynamic and transient analyses. Here are converged stress results on a casting. This configuration offers many benefits such as seamless interoperability with Creo Direct or Parametric with no data translation, a consistent user experience with other Creo apps, and seamless data management in Windchill.”Ĭreo Simulate delivers capabilities an analyst needs for structural and thermal simulation. The second is that Creo Simulate is based on the Creo platform. The adaptive P method solver assumes the responsibility for providing converged results – lessening the workload on the engineer or analyst as in other systems. “The first is that Creo Simulate is based on the same underlying solution technology as the company’s Mechanica solver.

There are two aspects that set Creo Simulate apart from other CAE packages, according to John Buchowski, PTC’s vice-president of product management.

Ideally, you can evaluate product performance and optimize designs early in the design process.

The software enables 3D virtual prototyping so you can test a range of structural and thermal properties of your design early in the detailed design process before you make the first physical part. One of the first new apps announced at PlanetLive 2011 is Creo Simulate. PTC is now beginning to deliver CAD and PLM software as individual Creo applications. Creo, as you might remember, was announced in October 2010 to replace existing Pro/Engineer, CoCreate, and ProductView products. The biggest news at the PlanetPTC Live 2011 event was the launch of the first set of Creo applications. Assemblies are as easy to simulate as individual piece parts.

0 kommentar(er)

0 kommentar(er)